• It can meet the requirements of multiple scenarios and operating conditions, such as conventional gas (containing moisture), liquid (containing bubble liquid), steam, as well as high viscosity, high freezing point, and solid powder containing fluids, such as crude oil, water-based crude oil, heavy oil, asphalt, residual oil, sewage, slurry and other media flow measurement;

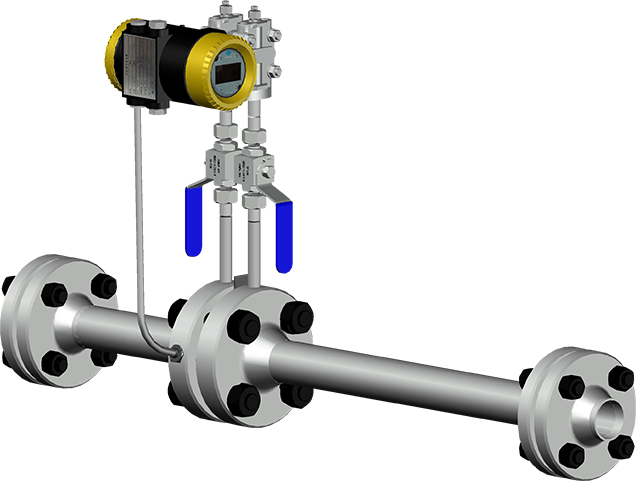

• Exquisite structure, replaceable throttling element, convenient for range adjustment and old well metering transformation (such as precession vortex);

• Developed using imported high-precision composite sensors and compiled according to the latest international standards;

• It can be equipped with various standard and non-standard throttling components such as standard orifice plates, conical orifice plates, balanced orifice plates, wedges, etc;

• Can be used for bidirectional metering, high viscosity media, and easy to crystallize media measurement processes;

• Can be used in high temperature, high pressure, high corrosion, and high sand content application environments;

• We have various pressure measurement and conduction schemes, such as air cushion isolation, displacement, double flange, etc., to cope with different application environments;

• Adopting a high-speed microprocessor and multi parameter design, it can achieve full range dynamic temperature and pressure compensation, and has display functions such as on-site differential pressure, pressure, temperature, flow rate, and cumulative flow rate;

• Non volatile memory with power down storage and data recovery functions;

• Equipped with self diagnosis and fault alarm functions, resistant to 50/60Hz power frequency interference;

• Scalable wireless communication.