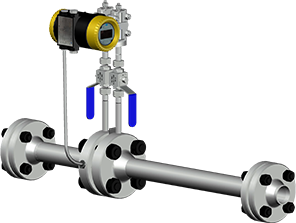

conical orifice flowmeter

-

Application occasions

Measurement of entrained liquid phase in gas-liquid medium (wet saturated steam flow and dryness measurement, gas condensate, coal-bed methane and Shale gas gas-liquid two-phase flow measurement, etc.). Of course, like other throttling flowmeters, it can

-

Structural composition

It is composed of conical orifice plate throttling components, instrument valves, pressure pipes, front and rear straight pipe sections, sensors, flow computers, etc.

-

Working principle

When two-phase flow passes through an orifice plate, there is differential pressure noise, known as differential pressure pulsation, on both sides of the orifice plate. This noise is an inherent characteristic of two-phase flow and is closely related to t