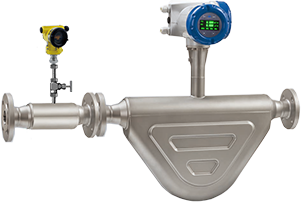

● Integrated design, simple structure, no radioactive source;

●Adopting German original imported sensors, with reliable technical performance

● Pipeline metering, with high safety, can be used for high temperature, high pressure, and high corrosion conditions

● Small size, light weight, land saving, especially suitable for space limited conditions;

● It can replace gas-liquid separation metering equipment, reduce investment, and simplify the process;

● Magnetic control+press operation, safe and fast parameter setting& Nbsp;

● Standard RS485 communication interface, capable of wired or wireless data remote transmission and upgrading& Nbsp;

● Suitable for all liquid to all gas phase changes& Nbsp;