● Small volume, no need for buffering - saving land, real-time online continuous measurement;

● Mature separation technology and corresponding solutions - high separation efficiency

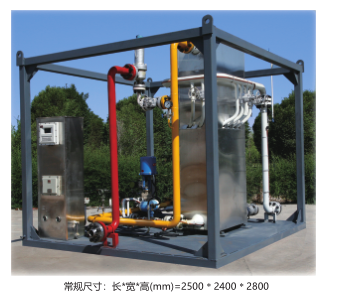

● Lightweight, compact structure, simple process - convenient for transportation and disassembly, easy to operate

● Dual gas path function, small liquid volume control function, and intelligent zone control technology - ultra wide range measurement, high accuracy, and able to meet the measurement of complex working conditions of valve groups;

● Self cleaning and anti sand treatment functions - ensuring long-term operation of the equipment

● Standardized production, overall factory testing - packaged transportation, ready to use, high reliability

● Belonging to pressure pipeline assembly - no need for annual pressure safety inspection, with low safety hazards

● Mature control technology scheme, instrument selection - suitable for various special working conditions

● Can be used as on-board measurement calibration and testing equipment

● It can display process parameter information such as liquid flow rate, gas flow rate, flow accumulation, temperature, pressure, liquid level, etc

● Paperless recording function, recording curves of various parameters, and permanently saving data during power outage

● Equipped with RS485 and RJ45 data communication interfaces as standard, data can be remotely transmitted through wired or wireless channels